Handling Bare Die

One of the greatest concerns of both semiconductor manufacturers and bare die users is the issue of handling bare die. It is easy to understand why handling bare die is such a universal concern. Bare die are fragile and special handling, storage, equipment, processes and trained personnel are required. After extensive testing, a die may start out as Known Good Die (KGD), but if it is not handled properly, it won’t be KGD for long.

From the initial receipt of product, electrostatic discharge (ESD) and contamination precautions need to be in place. All wafer/die products should be opened or removed from its original container in a clean room environment (minimum class 100K). All personnel and workstations should be grounded. Station checks for resistivity and resistance to ground need to be performed on a scheduled basis. In addition, daily checks of individual operator wrist straps are prudent.

The product is inspected to ensure that the supplier’s packaging will guarantee ESD and contamination protection, as well as visual and dimensional compliance. Although the outgassing and residual contamination left by “pink” polymer inserts can be detrimental to the die, some suppliers still use this type of insert. Semi Dice has determined, based on industry input and history, that “pink” polymer inserts should be removed immediately and replaced with an appropriate insert, such as Tyvek®, rice paper or silver saver. Due to ESD and environmental precautions, Tyvek is the preferred insert. Rice paper sometimes sticks to the die, resulting in lost product and lost production time due to reloading.

Once product is accepted, it needs to be moved for processing or to inventory. Product movement should take place with ESD and contamination control steps in place. Faraday Cage shielded bags, carriers or metal pans are the only acceptable means for product movement.

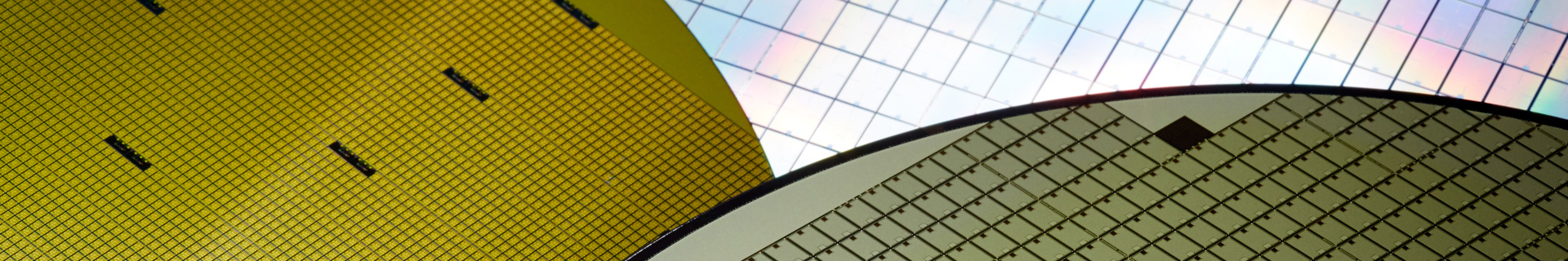

All bare die starts off in wafer form and must be sawed into individual dice. Wafers should be handled for mounting on a tape frame at a grounded work station with the operator wearing the wrist strap. Wafer sawing is done using de-ionized (DI) water, with the water resistivity monitored. ESD precautions, water contamination controls and resistivity minimize the migration of contaminates and silicon dust on the wafer surface. If required, the wafer is subjected to a wash of DI water and blown dry with nitrogen after sawing. Depending on the size of the die and wafer, the quantity of good die per wafer can range from less than 100 to 50,000 pieces.

The sawed wafer is then moved to the next operation — die removal from the tape. Typically, a de-mounter or automatic pick and place machine is used for separation. This has proven to be the most cost effective and “die friendly” method, since product is removed from the nitto tape separating devices with minimal contact between the die. (Bumping and rubbing of the devices causes chipouts and cracking.) Manual removal is employed when the customer requirements dictate adjacent die, wafer patterning, or special loading needs. Again, the individual operator performing the loading step is wearing the wrist strap and is working at a formal loading grounded area within the clean room environment. Station ionizers are often utilized at the loading area to lessen the chance of ESD damage.

The preferred manual loading tool is a vacuum pencil with pick-lip tip that accommodates the die size with minimal contact. Teflon®, metal., plastic and rubber are all acceptable tip materials. The use of tweezers for certain product types is also acceptable. Product is usually picked up with a vacuum pencil from the corner or side of the die. Large devices (200 x 200) would normally use a rubber tip with the pick-up from the top surface for loading.

Automated equipment may include a “pick and place” machine that removes the die from the tape. A video screen allows the operator to position the pick up collet over the center of the die. A needle(s) pushes up from the back and dislodges the die from the tape. The vacuum collet then lifts the die from the tape and places it into the carrier. This method is preferred for Gel-Pak® carriers because it produces consistent alignment of die onto the Gel-Pak. Manual loading does not allow for consistent placement and pressure of die onto the Gel-Pak membrane.

The proper handling of bare die at the loading operation is critical to the life of the die. Mishandling could inflict scratches, chips, cracking and contamination being transferred to the die. Working without proper ESD measures in place could cause latent electrical defects.

Chip carrier cavity size is determined by die dimensions (length, width and thickness) and is important to die safety. Die supplied in a cavity that is too large allows the chip to rotate or flip. The proper carrier will minimize die movement, yet permit ease of placement and die removal. Individual customer requirements may or may not be best suited to the device being supplied. Fluorware Chip Sentry™ is our preferred carrier type because the dimensional tolerances of the cavity walls allow for the chip to be placed in the carrier with minimal movement once inside. stat-PrO™ carriers do not have such precise inner dimensions and can cause loading and removal problems. In addition, lids are key in maintaining die placement. Dimpled lids are used for thinner devices. These lids assist in holding the insert to the top of the carrier surface, minimizing die movement within the cavity. Flat lids are used when the die height is just below the carrier surface. These lids do not add additional pressure when the insert is added and lid placed. A flat lid may require two or more inserts to ensure the devices remain within the cavity. When using a dimpled carrier, only one insert is needed.

Once the product has completed its cycle through the saw, load and visual operations, storage is the next area of concern. Due to the temperatures many devices are subjected to during manufacturing and test cycles, temperature is not an issue of concern. However, most devices and many metal compositions are susceptible to the environmental concern of moisture. For example, product with silver back metal or bond pads could, over time and if not stored properly, experience metal corrosion or tarnish. This can result in adhesion or bondability issues.

It is our standard practice to store “environmentally sensitive” product is in a dry box. The typical dry box is a Plexiglas container filled with a continuous flow of nitrogen, as well as door seals to ensure the inner atmosphere remains somewhat inert. Routinely monitoring the nitrogen flow, humidity indicators and regular inventory audits will ensure that the product has not started to degrade, as well as ensure that contamination has not been introduced.

Product that is not “environmentally sensitive” may be stored in an open atmosphere when properly packaged. Proper packaging would include the correct carrier and insert with the appropriate clip and lid. Placement in a sealed ESD bag or enclosed container will provide additional safeguards. Again, regular inventory audits should be performed to ensure that contamination is not introduced to the product.

Handling bare die will always be an issue because of the many processes involved and the sensitivity of the die. However, the risk of lost product can be greatly reduced with the right equipment, procedures and proper training.

1The Second Annual Semi Dice Inc. Bare Die Survey