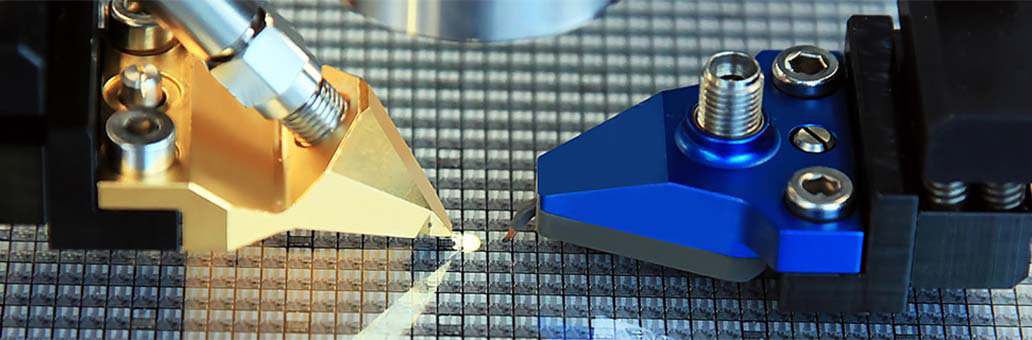

Semiconductor manufacturers use wafer probing as a first characterization of the parts on the wafer. It is not meant to be the final test of the device which comes after it is packaged. The manufacturer chooses probe tests and limits to find and remove die that are not worth packaging. SemiDice can re-probe a wafer to tighter limits to select die that meet a customer’s specific requirements. We can probe at room temperature or we can hot chuck probe the wafer at an elevated temperature to give a better indication of how the parts will work in a high temp application. The nominal added cost of a special probe can easily be offset by the improvements in circuit yield that the circuit builder will enjoy. Wafers you supply, or wafers from our partners can be re-probed to enhance your yields. Sample probed wafers can be 100% probed for use in circuits where every device must be tested.